INTERNAL ROTATING INSPECTION SYSTEM (IRIS) is a method used in the inspection of pipes and vessels.

IRIS uses ultrasonic technology and rotating sensors to generate images of the internal surface of cylindrical objects, providing a detailed view of any anomalies or defects in the material.

IRIS is often used in industrial applications to assess the integrity and condition of pipes and vessels, and to detect corrosion, cracks, and other types of damage. The method is particularly useful for inspecting the internal surface of pipes and vessels that are difficult to access or that contain hazardous materials.

The purpose of Eddy Current Testing (ET) is to detect and evaluate surface and near-surface discontinuities and defects in conductive materials.

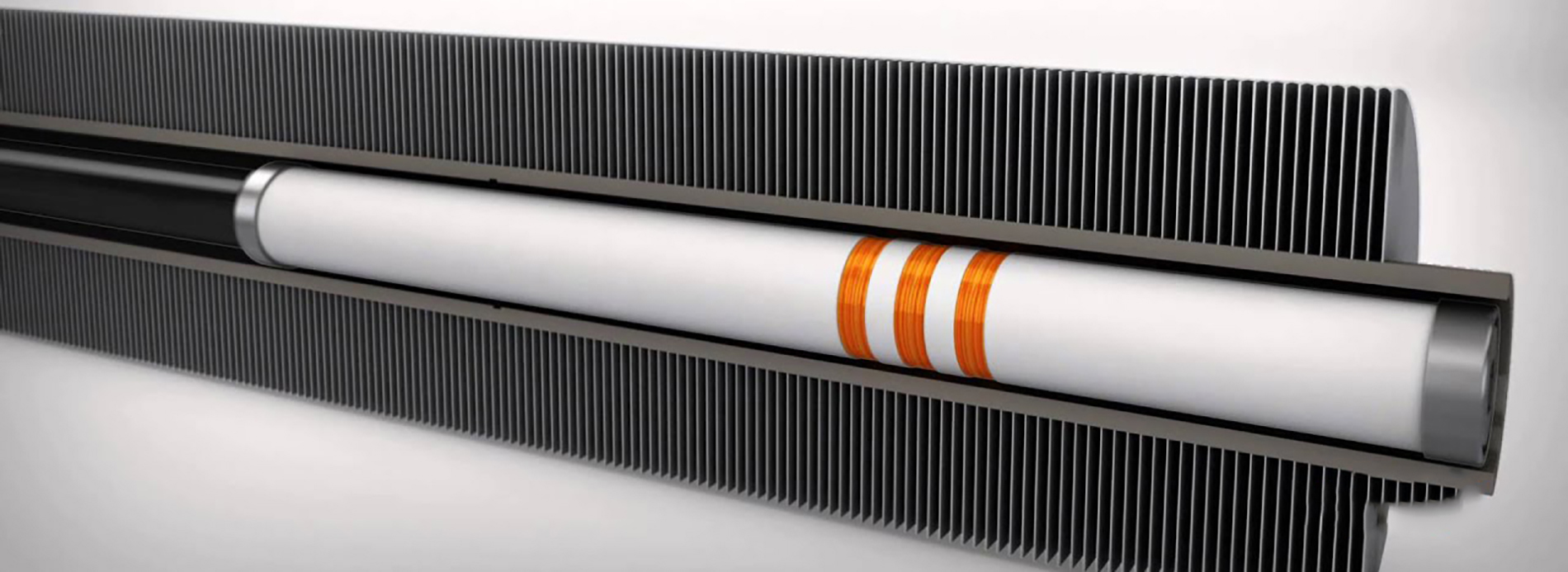

The purpose of Remote Field Testing (RFT) is to detect and evaluate defects in ferromagnetic pipes and tubes. Remote field testing is a type of non-destructive testing that uses magnetic fields to inspect the internal surface of ferromagnetic pipes and tubes. The test equipment generates a magnetic field that penetrates the material being tested and generates eddy currents on the internal surface of the pipe. The eddy currents create a secondary magnetic field that is detected by a sensor.

Remote field testing is particularly useful for inspecting pipes and tubes that are difficult to access or that contain hazardous materials. Remote field testing is a fastest non-destructive way to inspect ferromagnetic pipes and tubes, and it provides high sensitivity for detecting near-surface and subsurface defects.

The purpose of Near Field Testing (NFT) is to detect and evaluate defects in conductive materials using magnetic fields. Near field testing is a type of non-destructive testing that uses magnetic fields to inspect the surface of conductive materials for cracks, corrosion, and other types of defects. The test equipment generates a magnetic field that penetrates the material being tested, and the magnetic field is sensed by a detector.

Near field testing is particularly useful for inspecting conductive materials that are difficult to access or that contain hazardous materials. Near field testing is a fast and non-destructive way to inspect conductive materials, and it provides high sensitivity for detecting near-surface defects.