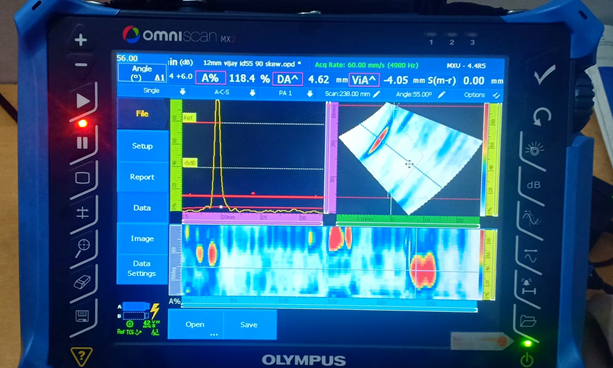

Phased Array Ultrasound Testing (PAUT) is a type of non-destructive testing (NDT) technique that uses ultrasound to inspect materials for defects or anomalies. In PAUT, multiple ultrasound transducers are combined in an array and used to scan the material simultaneously, providing a faster and more comprehensive inspection than traditional ultrasonic testing. The use of phased arrays allows for the real-time adjustment of the direction and focus of the ultrasound beam, making it possible to inspect complex geometries and multiple angles in a single pass. PAUT is widely used in various industries including aerospace, power generation, and oil and gas. It is also particularly useful in situations where there is less room for mechanical scanning because it’s able to sweep the beam without moving the probe.

Course Description:

The general theory covered includes:

• Principles of Phased Array probes

• Principles of inspection sensitivity

• Phased Array Instrument

• Scanning with Phased Array probes

• Calibration and checks

• Software for data collection and data analysis

• Principles of data analysis

• Software familiarity

• Use of software tools for defect detection and sizing

• Data analysis

• Procedures for verification of flaw existence and position

• Reporting

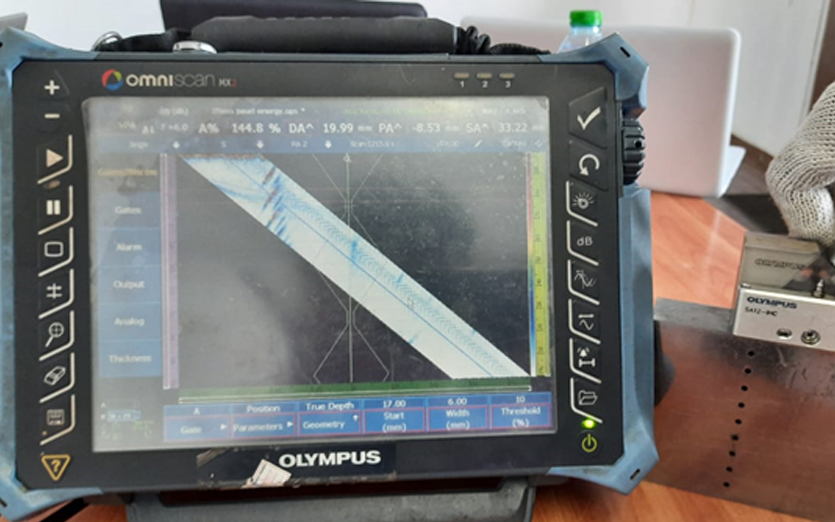

Time of flight diffraction (TOFD) is a non-destructive testing (NDT) technique used to detect and size defects in materials such as metal plates and pipes. It works by transmitting ultrasonic waves into the material and measuring the time it takes for the waves to travel to the defect and back. The resulting waveform is analyzed to determine the location and size of the defect. TOFD is highly accurate and provides a fast and reliable method for detecting defects in structures that are difficult to inspect using other NDT methods, such as those with complex shapes or heavy corrosion. It is widely used in the petrochemical, nuclear power, and shipbuilding industries, among others.

Course Description:

• TOFD introduction and history

• TOFD vs other methods

• Tip diffraction

• Fundamentals of TOFD

• Equipment setup and parameters selection

• Digitizing principles

• Data analysis and sizing

• Codes and standards

• Reports

Certificate:

Training of PAUT and TOFD are in accordance with the requirements of ASNT as per SNT-TC-1A-2016 and the course ends with the certification examination.

Training requirements:

The minimum required duration of training, which includes both theoretical and practical elements, is:

• Level 2 - 80 hours

Equipment:

Equipment for PAUT and TOFD:

• Omniscan MX2 with 16/128 or 32/128 module (PR module)

• Mini wheel encoder assembly complete with brackets and screws

• Memory card reader to download data to computer

• 5L64 A12,2.25L62 A32, A27 probes are available for PAUT

• SA12 N55S IHC, SA32 N55S IHC, SA32 0L IHC all wedge sets for A27 probes angled wedge for PAUT

• HST-X01, flexi scanners are available for plates and pipes for PAUT and TOFD

• C543, C563 probes for TOFD

• ST1 70L IHC, ST1 60L IHC, ST1 45L IHC.