What is NDT?

Non-destructive testing is a part of quality control inspection that doesn’t alter the geometry or structure of the material being inspected. The NDT inspectors are using sophisticated analytical instruments and technologies to look through the quality of the materials and identify the flaws/discontinuities without disturbing the integrity of the part/structure/component being tested. Training is in accordance with the requirements of ASNT as per SNT-TC-1A-2016 and the course ends with the certification examination.

Job opportunities

There are tremendous job opportunities are available for NDT Technicians, Inspectors and Engineers in various type of industries such as Refinery, Oil and gas, Petrochemical, Power plants, Nuclear, Wind, Hydro, Aerospace, Earth movers, Railway, Ship building and various fabrication and erection sites.

Conventional NDT

This course will cover the properties of materials, theory of corrosion, erosion, types of corrosion, and preventative measures (likely locations, inspection and monitoring techniques, variables affecting corrosion). You will also learn about corrosion monitoring, structural damage mechanisms, degradation of materials in-service conditions, and types of failure.

This course will teach you about the principles of magnetism, magnetic fields, induction, permeability and reluctance, and magnetisation. You will also learn about lines of force, methods of testing, interpretation of indications, demagnetisation, practical exercises, methods of assessing sensitivity, and instruction writing.

Training requirements:

The minimum required duration of training, which includes both theoretical and practical elements, is:

• Level 1 - 16 hours

• Level 2 - 24 hours (Direct Level 2 - 40 hours)

Certification requirements:

The minimum duration for experience prior to or following success in the qualification examination is:

• Level 1 - 1 month

• Level 2 - 3 months (Direct Level 2 - 4 months)

This course will cover basic principle, methods, compatibility of materials, equipment, properties of penetrant, steps in liquid penetrant testing, interpretation, recording, and safety aspects as per codes and standards.

Training requirements:

The minimum required duration of training, which includes both theoretical and practical elements, is:

• Level 1 - 16 hours

• Level 2 - 24 hours (Direct Level 2 - 40 hours)

Certification requirements:

The minimum duration for experience prior to or following success in the qualification examination is:

• Level 1 - 1 month

• Level 2 - 3 months (Direct Level 2 - 4 months)

Certification will not be issued until successful completion of the examination and the required experience is achieved.

This course will teach you about welding processes and weld defects, properties of X- and gamma-rays, film selection, developing. You will also learn about factors controlling contrast and definition, X- and gamma-ray equipment, ionising radiation hazards, regulations, use of screens and filters, selection of angle of aspect, image quality indicators, defect depth location, castings, and reporting. This course will offer also about Radiation safety and knowledge about the usage of radiation safety accessories You will receive training relevant to the examination to be taken covering practical, inspection and theoretical aspects as appropriate.

Training requirements:

The minimum required duration of training, which includes both theoretical and practical elements, is:

• Level 1 - 40 hours

• Level 2 - 80 hours (Direct Level 2 - 120 hours)

Certification requirements:

The minimum duration for experience prior to or following success in the qualification examination is:

• Level 1 - 3 months

• Level 2 - 9 months (Direct Level 2 - 12 months)

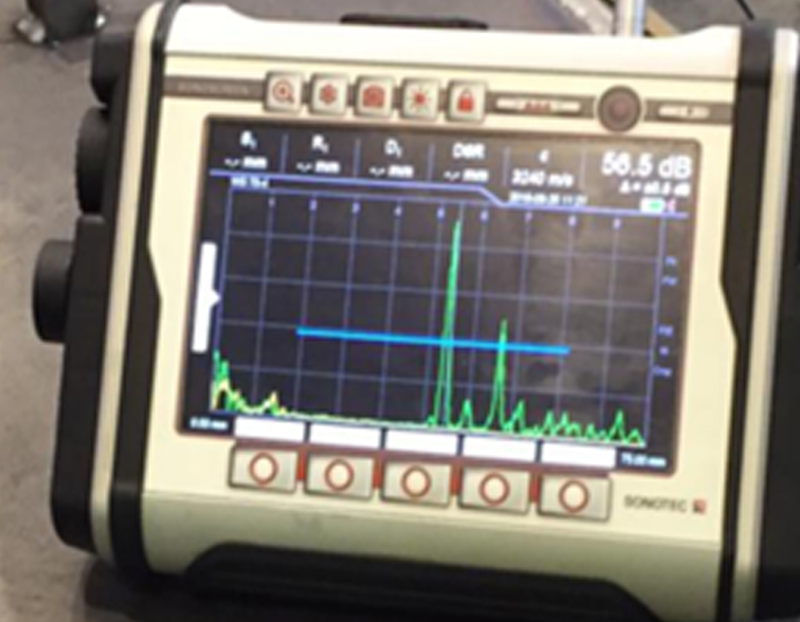

This course will cover basic principles of sound; generation and detection of sound; behaviour of sound in a material; the flaw detector; use of angled beam probes for weld scanning; welding processes and weld defects; practical exercises on standard calibration and reference blocks, test specimens containing simulated flaws; examination of parent plate, butt welds; instruction writing, interpretation and record of indications as per codes and standard

Training requirements:

The minimum required duration of training, which includes both theoretical and practical elements, is:

• Level 1 - 40 hours

• Level 2 - 80 hours (Direct Level 2 - 120 hours)

Certification requirements:

The minimum duration for experience prior to or following success in the qualification examination is:

• Level 1 - 3 months

• Level 2 - 9 months (Direct Level 2 - 12 months)

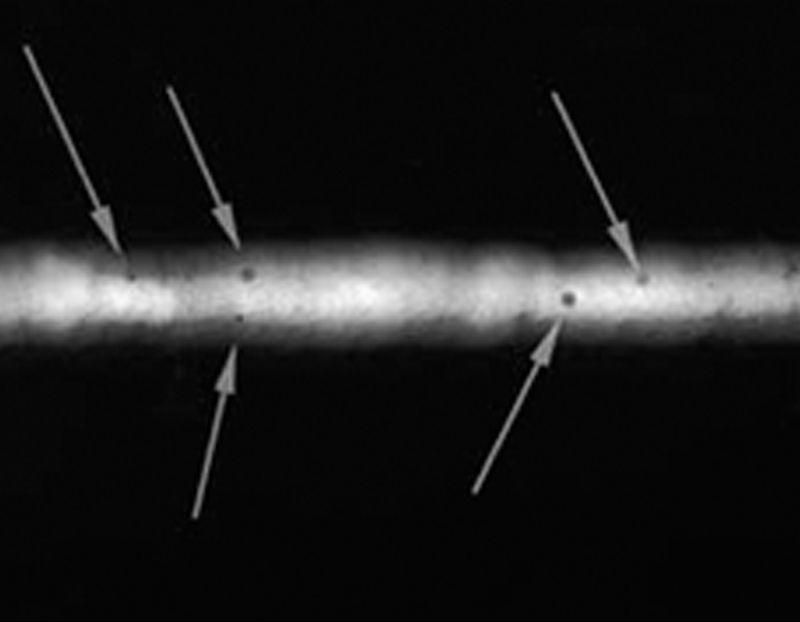

The important part of training is spent on interpretation exercises. For each student a comprehensive set of radiographs is prepared. The difficulty level of assigned tasks is gradually increased so students will progress from basic of interpretation to advanced level.

During each interpretation session all students are assigned the same task but carry out interpretation independently from the rest of group under guidance of an experienced tutor. Radiographic interpretation is followed by sets of multiple-choice questions focused on key areas of radiograph. The questions provide additional valuable guidance to the student. Each of the sessions is closed by an open discussion on the correct answers and reporting. This open discussion environment provides additional learning outcomes – students can gain knowledge about improper handling of films, film processing marks, interpretation on welding, casting and forged components.

Training requirements:

The minimum required duration of training, which includes both theoretical and practical elements, is:

• Level 1 - not applicable

• Level 2 - 56 hours

Certification requirements:

The minimum duration for experience prior to or following success in the qualification examination is:

• Level 1 - not applicable

• Level 2 - 6 months

Introduction to visual inspection; fundamentals of vision and light; introduction to NDT; visual inspection equipment; factors influencing visual inspection product technology (welding, casting, forging etc.); practical inspection methodology; inspection, weld repair and heat treatment requirements.